Modern manufacturing demands efficiency and precision. Industries require high-quality parts produced quickly, often with strict requirements for strength and consistency. Cold heading provides a proven solution for creating various components, from fasteners to automotive parts.

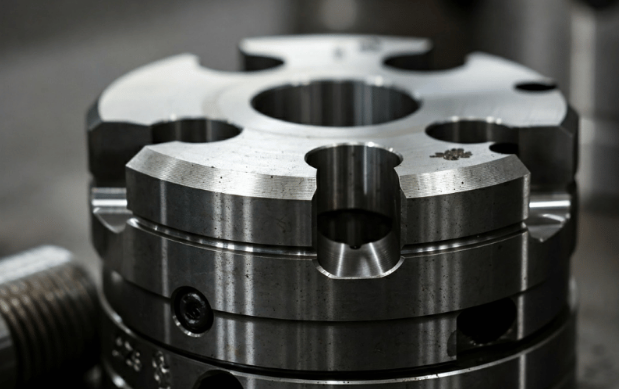

At the core of this process are cold heading dies, specialized tools that shape metal with force and accuracy. They are vital for achieving complex geometries and tight tolerances needed in many applications. This blog will explore the ins and outs of cold heading, examine its advantages, applications, and the important role cold heading dies play.

The Cold Heading Process

Cold heading is a metal-forming process performed at room temperature. It involves using a series of dies to shape a wire or rod into a desired form. The process begins with a wire or rod cut to a specific length. This blank is then placed into a die, and a punch applies force to deform the metal. Through a series of die cavities, the metal is gradually shaped into the final product.

The “cold” in cold heading refers to the temperature at which the process occurs. Unlike hot forming, where metal is heated to become more malleable, cold heading takes advantage of the metal’s inherent properties at an ambient temperature. This option offers several benefits, including improved strength and surface finish.

Parts that have undergone the cold heading process exhibit notable characteristics, such as increased grain density and dimensional accuracy, compared to parts produced through other methods like machining. Cold heading is particularly well-suited for creating parts with symmetrical shapes and heads, like screws, bolts, and rivets.

Steps in the Cold Heading Process

Understanding the steps involved in cold heading provides a clearer picture of what “cold headed meaning” represents. While the precise sequence may vary depending on the part’s complexity, the common stages include:

Shearing

The process begins with feeding a wire or rod of the required material into the machine. A shear tool cuts the wire into precise blanks, providing the starting point for the cold heading process.

Upsetting

Often the first stage of deformation, upsetting involves placing the blank in a die. The force coming from a punch compresses the metal and increases its diameter. This effectively “upsets” the original shape and forms the head of fasteners like screws or bolts.

Heading

The upset blank transfers to a new die cavity where a precisely shaped punch strikes the metal. This forces the material to flow and conform to the die’s contours, creating the final head form. The accuracy and durability of carbide dies are essential in this stage, especially for parts with complex shapes that require multiple heading operations.

Extruding

If the part needs a reduced diameter section or a specific feature like a groove, an extrusion step comes next. The machine forces the metal through a die opening, which reduces the cross-sectional area.

Trimming

Heading sometimes produces excess material or flash. A trimming operation removes this excess, ensuring the final part meets dimensional requirements.

Pointing

If a pointed end is necessary, as with a screw, a pointing operation shapes the end of the part using a specialized die.

Thread Rolling

For threaded fasteners, thread rolling occurs after the heading process. The machine rolls the part between dies with the desired thread pattern, creating threads without removing material.

Tool Maintenance

An essential aspect of cold heading involves maintaining the dies and other tooling components to ensure consistent accuracy and performance. Proper maintenance of carbide dies and other tools ensure longevity and consistent part quality.

The precisely controlled deformation inherent in each stage of cold heading results in components that exhibit enhanced grain structure, superior strength, and precise forms. This combination of attributes defines the essence of cold heading: an efficient method for producing high-quality components from simple wire.

Advantages of Cold Heading

The cold heading process offers numerous benefits that make it a preferred choice for various manufacturing applications:

- High Production Speed: Cold heading is an incredibly fast process, capable of producing thousands of parts per hour. This high production rate contributes to lower manufacturing costs and quicker lead times.

- Enhanced Material Strength: The cold working of the metal during the cold heading process increases its strength and hardness. This results in more durable components that are resistant to wear and tear.

- Cost-Effectiveness: While the initial investment in cold heading dies can be significant, the long-term cost savings are substantial. The high production speed, reduced material waste, and minimal secondary operations contribute to overall cost efficiency.

- Improved Material Utilization: Cold heading generates very little material waste compared to other processes like machining, making it a more sustainable and environmentally friendly option.

- High Precision and Accuracy: Cold heading can achieve tight tolerances and intricate shapes, ensuring that parts meet exact specifications. This reduces the need for secondary machining operations, saving time and additional costs.

- Excellent Surface Finish: Cold-headed parts typically have a smooth surface finish, which can be crucial for applications where aesthetics or reduced friction are important.

Disadvantages of Cold Heading

While cold heading offers numerous advantages, it’s essential to consider its limitations:

- Part Complexity: Cold heading might not be feasible for intricate designs with undercuts. The process generally works best for parts with symmetrical shapes and relatively simple geometries.

- Size Restrictions: The size of parts that can be produced is limited. Extremely large or long components might not be suitable for cold heading.

- Upfront Costs: The initial investment in cold heading dies can be significant, especially for complex parts. However, these costs are often offset by the long-term efficiency and material savings of the process.

- Material Suitability: Not all materials are ideal for cold heading. Those that are too brittle or lack sufficient ductility may crack or fracture during the process.

Despite these limitations, cold heading remains a highly efficient and cost-effective solution for many applications. Careful consideration of part design and material selection can mitigate potential challenges.

Applications of Cold Heading

The versatility of the cold heading process makes it a popular choice across diverse industries, including the following key sectors:

- Automotive: From fasteners and bolts to engine components and suspension parts, cold heading produces numerous parts vital for vehicle assembly.

- Aerospace: The aerospace industry demands high-strength, lightweight components. Cold heading delivers, creating parts used in aircraft structures, engines, and control systems.

- Construction: Nails, screws, and other fasteners used in construction often undergo cold heading for enhanced strength and durability.

- Electronics: Small, intricate components found in electronic devices and appliances, such as connectors and terminals, can be efficiently produced through cold heading.

- Medical: The medical industry utilizes cold heading to manufacture precise components for surgical instruments and medical implants.

The ability to produce strong, accurate parts at high speed makes cold heading a preferred method for creating essential components. For more examples of cold heading applications and how the process serves different industries, visit our website.

Cold Heading vs. Other Cold Forming Processes

While cold heading is a prominent method among cold-forming processes, it’s not the only option. Other techniques, such as cold forging, extrusion, and stamping, also shape metal without heat. However, key differences set these methods apart.

Cold forging involves shaping metal using compressive forces within a die cavity. This process creates more complex geometries than cold heading but often requires higher tonnage presses and more intricate die designs. Extrusion pushes metal through a die to make long, uniform shapes with a constant cross-section. Stamping uses a punch and die to cut or form sheet metal.

The choice between these processes depends on the specific application and desired part characteristics. Cold heading excels in producing smaller, high-volume parts with symmetrical shapes and heads, such as fasteners and pins. The efficiency and speed of the cold heading process, combined with the precision of cold heading dies, make it a cost-effective solution for these applications.

In contrast, cold forging is better for larger, more complex parts with asymmetrical features. Extrusion is ideal for creating long, continuous shapes like rods and tubes, while stamping is preferred for flat or sheet metal components.

As a manufacturer, you need to understand the strengths and limitations of each cold-forming process. This knowledge will enable you to select the most suitable method for your needs and desired part characteristics.

Choosing the Right Cold Heading Company

The success of a cold heading project hinges on partnering with the right company. Expertise, experience, and a commitment to quality are essential factors to consider. Look for one with a proven track record in cold heading, a deep understanding of cold heading dies, and the ability to provide customized solutions tailored to your needs.

Ready to discuss your specific requirements? Contact us at Raven Carbide Die today!