Made in USA

“The Carbide Die Specialists”™

Made in USA

“The Carbide Die Specialists”™

If you want the best end products manufactured at the lowest real price (price per piece plus higher quality benefits), then you want to form your metal using RCD carbide dies. Raven Carbide Die assures you of a tight tolerance and a long lasting die – all at a low price and with prompt delivery. Basically, with RCD you get unbeatable products and customer service from the custom carbide die specialists™.

Discover high-quality tungsten carbide punches for precise and durable metal stamping applications.

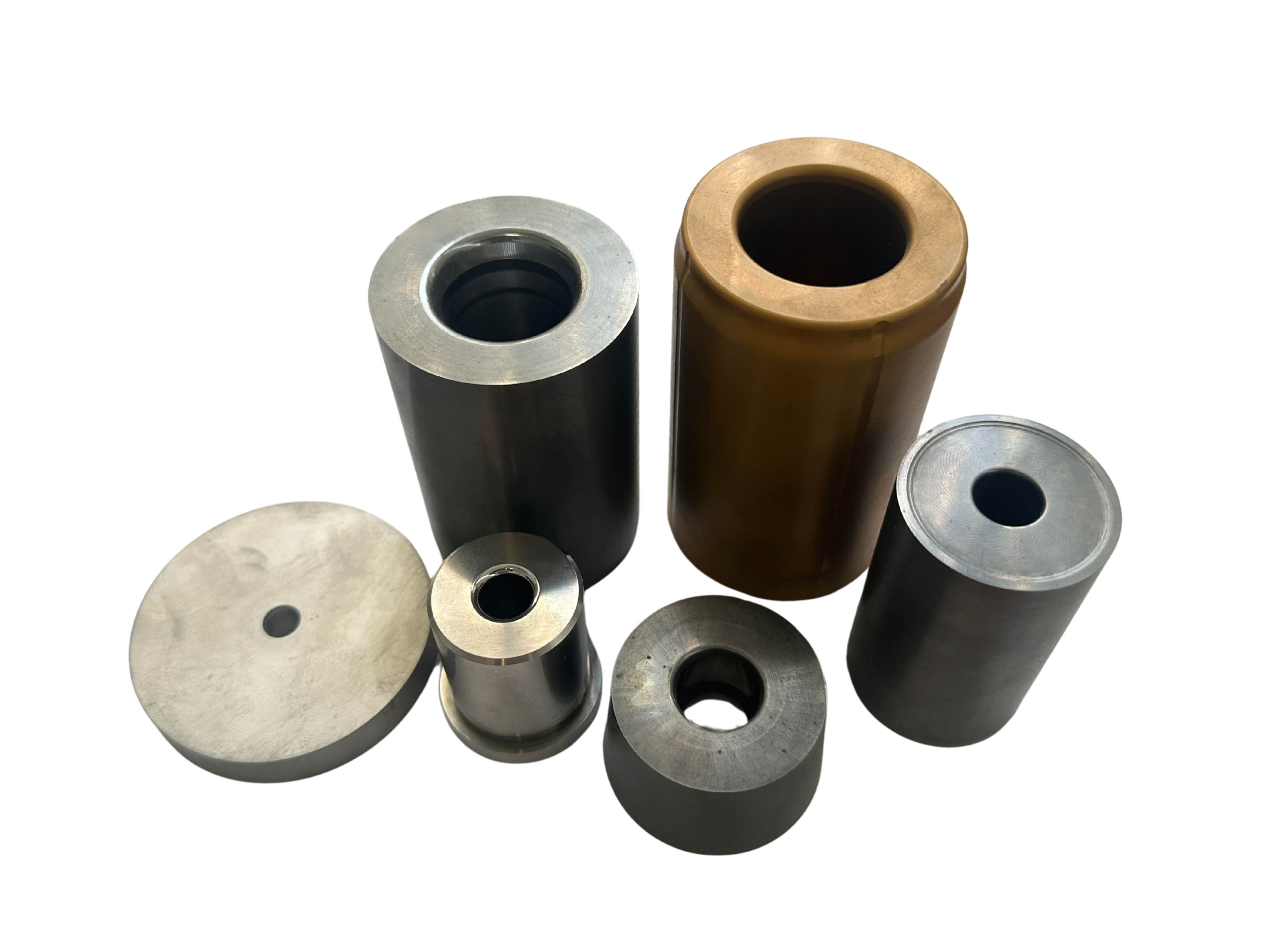

Raven Carbide Die specializes in producing long lasting, high quality, carbide cold heading dies.

RCD produces the highest quality carbide drawing dies, also referred to as draw dies, for use in making wire, pipe (tubing), rods and bars.

Raven Carbide is a manufacturer of custom and standard industrial tungsten carbide headless press fit bushings.

RCD specializes in producing long lasting, high quality, tungsten carbide extrusion dies.

Raven Carbide Die manufactures carbide cold forming dies (also called header dies or cold heading dies) for cold heading and cold forming operations. In fact, this is our specialty.

We understands the extreme pressures carbide dies are under, so we focus on manufacturing the highest quality, longest lasting dies in the industry.

Raven Carbide Die produces carbide drawing dies in all the standard configurations (round, square, hexagonal and rectangle) and in custom shapes as specified by our customers drawings.

RCD drawing dies are typically used to draw wire, rod, bar, and tube. Commonly drawn materials include steel alloys, aluminum alloys, and copper alloys. See draw dies for more information.

With over 40 years of experience behind us, RCD can manufacture a wide variety of extrusion dies and tooling. Examples include both extrusion and pointing dies, and all extruding tooling such as mandrels, dummy blocks and die holders. Basically we produce any tooling you need for your extrusion process. Similarly, Raven Carbide Die is highly proficient in the production of calibration dies for high performance applications such as calibrating bearings.

RCD manufactures both shaving dies and inserts in a wide range of sizes and with a variety of rake or face angles.

Shaving dies are typically used to remove surface defects that are introduced in the drawing process. The shaving process can be used on steel alloys, aluminum alloys, and copper alloys.

RCD also produces tungsten carbide swaging dies, in one, two or four piece configurations. With RCD tungsten carbide swaging dies you receive a significantly longer lasting die, made to your specifications.

RCD swaging dies are generally used in a manufacturing process commonly referred to as rotary swaging. In rotary swaging, a point is created out of a material using a swaging die, this taper is then sized correctly to be used in the next operation which could be extruding or cold drawing.

RCD manufactures mandrels and plugs. Including braze-type mandrels, shaped mandrels, sleeve mandrels, floating plugs, single pointing dies and push pointing dies.

And More!

RCD also produces a wide variety of high quality carbide bushings and custom carbide tooling for cold heading and cold forming. Yet another specialty is our hichly aclaimed and accurate carbide ammunition dies.

And More!

RCD also produces a wide variety of high quality carbide bushings and custom carbide tooling for cold heading and cold forming. Yet another specialty is our hichly aclaimed and accurate carbide ammunition dies.

Raven Carbide Die can make your dies to any carbide grade you specify, however, if you would like a recommendation our expert team will be more than happy to advise you on which grade will be best suited for your operations. For example, one grade will yield more stainless steel parts while others will be more efficient when forming copper. RCD can analyses how your dies wear out and refer to years of experience to recommend the correct tungsten carbide for you. Furthermore, we will work with you to analyze and perfect your dies performance through feedback and testing. Contact us to receive our free analysis and a competitive quote.

©2025 Raven Carbide Die Copyright All Right Reserved.