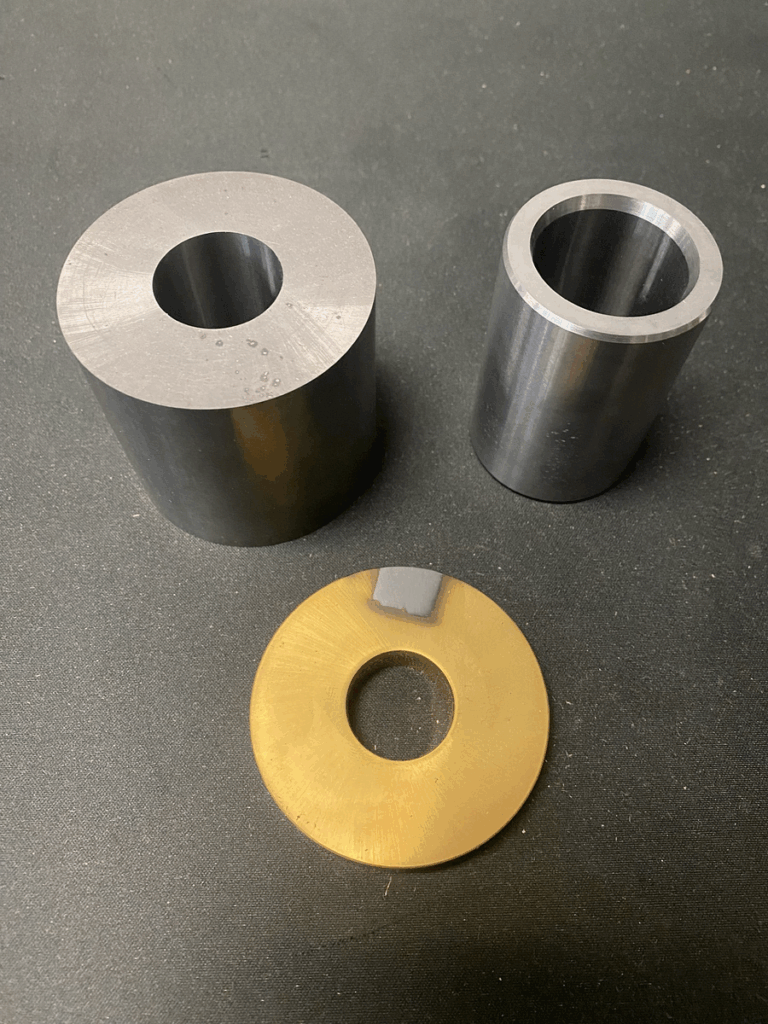

When it comes to choosing the right tooling for manufacturing, especially dies, the decision often comes down to carbide dies or steel dies. Both materials have their place, but if you’re after long-term performance, reduced downtime, and consistent quality — carbide might be the better investment. Here’s how they stack up.

Durability and Wear Resistance

Steel dies are known for their strength and affordability, but when subjected to heavy loads, repeated use, or abrasive materials, they can wear down relatively quickly. In contrast, carbide dies, made from tungsten carbide, are significantly harder and more wear-resistant. This allows carbide dies to maintain their edge and integrity much longer than steel, especially in high-volume or high-pressure environments.

This results in fewer replacements, less downtime, and longer intervals between tool changes.

Precision Over Time

Tight tolerances are critical in industries like automotive, aerospace, and ammunition. While steel dies may perform well initially, they tend to degrade faster, affecting dimensional accuracy. Alternatively, carbide dies retain precision over extended use, reducing part rejection and ensuring better quality control across the board.

If consistency is key to your operation, carbide has a clear edge.

Performance in Harsh Conditions

In applications involving high heat, corrosive materials, or extreme pressure, carbide’s superior physical properties make it the more reliable option. It resists deformation, chipping, and thermal breakdown better than most steel alloys.

For jobs that push your tooling to the limit, carbide dies can handle more abuse without compromising performance.

Cost and Long-Term Value

There’s no denying that steel dies come with a lower upfront cost. For short production runs or lower-stress applications, they might be the more economical choice. However, in operations where uptime and part quality matter, the higher initial cost of carbide dies is often offset by their lifespan.

Over time, carbide dies pay for themselves by lowering replacement frequency, reducing maintenance, and keeping your machines running longer.

When Steel Still Makes Sense

There are situations where steel might be the practical choice — for example, when working with softer materials, running very short production cycles, or operating under budget constraints. But for growing operations aiming to reduce inefficiencies and scale up quality, carbide is typically the better long-term bet.

The Verdict

While steel dies are still widely used and suitable for many applications, carbide dies offer clear advantages when it comes to longevity, precision, and performance. If you’re serious about reducing tooling costs over time and maintaining production quality, it’s worth considering a shift to carbide.

At Raven Carbide Die, we specialize in custom carbide solutions built to handle demanding environments. If you’re interested in improving output while minimizing maintenance and replacement costs, we’d love to talk about how carbide dies can fit into your operation.